Material: Graphite

Welding Current: DC 150~1600A

Pointed Copper -Coated ,Jointed & Non Jointed Gouging Carbon Rods,use for cutting welding defects removing ,making holes ,welding inspeciton

| PART NO. | NJ & JOINTED |

| APPLICATION | GOUNGING CARBON RODS FOR CUTTING WELDING DEFECTS REMOVING, MAKING HOLES ETC. |

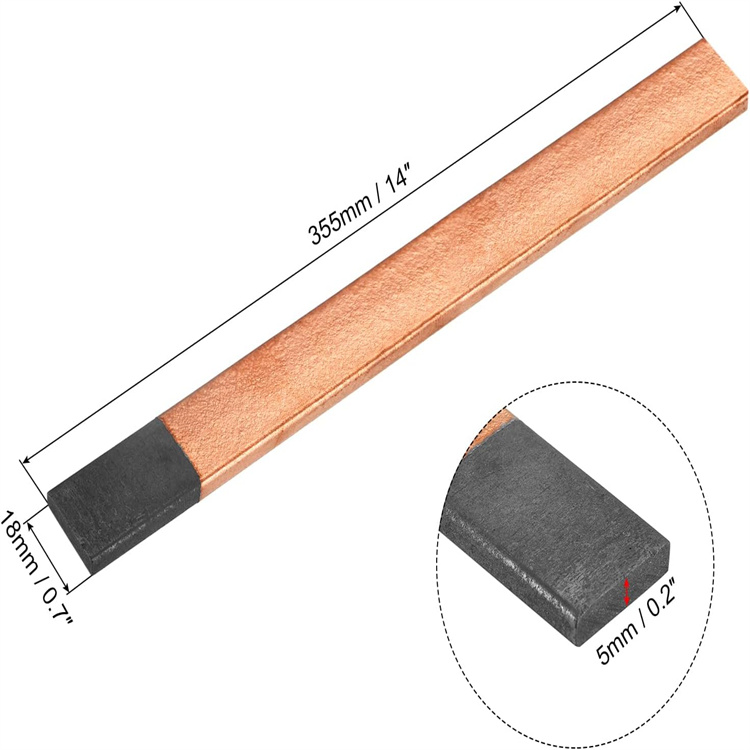

| LENGTH | 305MM/355MM/455MM/510MM |

| ANGLE | 3.2/4/5/6/6.5/7/8/9/10/11/12/13/16/19/25MM |

| DIAMETER | 5MM/8MM/10MM/12MM/15MM |

| CURRENT RANGE | 130-1600A |

| CERTIFICATION | ISO9001, CCC |

Diameter * Length ( mm ) | Diameter * Length ( inches ) | Current Range ( A ) |

3.2*305 | 1/8*12' | 130-180 |

4*305(355) | 5/32*12'(14') | 150-200 |

5*305(355) | 3/16*12'(14') | 200-250 |

6*305(355)(400)(455)(510) | 15/64*12'(14')(16')(18')(20') | 15/64*12'(14')(16')(18')(20') |

6.5*305(355) | 1/4*12'(14') | 320-370 |

7*355 | 9/32*14' | 350-400 |

8*305(355)(400)(455)(510) | 5/16*12'(14')(16')(18')(20') | 400-450 |

9*305(355) | 23/64*12'(14') | 450-500 |

9.5*305(355) | 3/8*12'(14') | 500-550 |

10*305(355)(400)(455)(510) | 3/8*12'(14')(16')(18')(20') | 550-600 |

11*305(355) | 7/16*12'(14') | 600-650 |

12*305(355) | 15/32*12'(14') | 750-850 |

12.7*305(355) | 1/2*12'(14') | 800-1000 |

13*305(355) | 1/2*12'(14') | 800-1000 |

16*305(355) | 5/8*12'(14') | 1000-1200 |

19*305(355) | 3/4*12'(14') | 1200-1400 |

Air carbon arc gouging works as follows. An electric arc is generated between the tip of a carbon electrode and the workpiece. The metal becomes molten and a high velocity air jet streams down the electrode to blow it away, thus leaving a clean groove. The process is simple to apply (using the same equipment as MMA welding), has a high metal removal rate, and gouge profile can be closely controlled. Disadvantages are that the air jet causes the molten metal to be ejected over quite a large distance and, because of high currents (up to 2000A) and high air pressures (80 to 100 psi), it can be very noisy.

As air carbon arc gouging does not rely on oxidation it can be applied to a wide range of metals. DC (electrode positive) is normally preferred for steel and stainless steel but AC is more effective for cast iron, copper and nickel alloys. Typical applications include back gouging, removal of surface and internal defects, removal of excess weld metal and preparation of bevel edges for welding.

Instructions for Use:

1. The carbon rod must be kept dry, and it can only be used after being dried when wet.

2. When used in DC power supply, the carbon rod is connected to the positive pole of the power supply, and the workpiece is connected to the negative pole.

3. The compressed air pressure should be kept at 0.5-1.6MPa.

4. The arc distance between the carbon rod and the workpiece is about 3mm, and the exposure of the carbon rod to the fixture is about 100mm.

5. The carbon rod forms an angle of 45° with the workpiece, and is planed along the tangent (or straight) direction.

6. The carbon rod must be well ventilated when using it and operate according to the working current.

Contact: admin

Phone: +86-13665233012

E-mail: service@weldmaterial.com

Add: Huanghua Industrial park, Jiangdu City, Yangzhou , Jiangsu Provicne, China.